Learn The Ins and Outs Of Indoors and Vertical Aquaponics! Part 1

Vertical Aquaponics, Part 1:

People often equate “vertical aquaponics” with “indoor aquaponics”. We live indoors; why can’t plants? Greenhouses can seem mysterious and confusing if you’re not familiar with them. Growing things inside a building, under lights that you can turn on and off, may seem simpler.

But there’s no free lunch; it turns out that growing indoors is fraught with complications, many of which are blithely ignored by those trying to sell you the buildings, the grow systems, LED lights, farm plans, and hardware necessary to do this.

(Below) A pretty picture to go with this newsletter’s message: Farmed Here, a large indoor aquaponic operation that declared bankruptcy in March of 2017, after 8 years of operation and “looking for investors”.

We’re going to debunk the nonsense surrounding vertical growing in this series of articles, and leave you with a clear understanding of what it involves, what it costs, and where it might be profitable. Then, you can make an intelligent decision rather than be sucked in by the first hardware salesperson with a good line of patter.

As part of this series, we’re including the information in our “Aquaponics For Millionaires” disclosure package at no charge. We’ve been selling this information package for $1,000 (because to a millionaire, that’s like a cup of coffee is to you, right?).

It’s just the disclosure package we’re providing, not the design and calculations, the CAD drawings, nor all the work required to design a large custom indoors aquaponic operation. Our fee for performing that work can run $75,000 on up. But if you read this, and you’re smart, you can figure it all out yourself. Here’s the first part:

Air Conditioning For The Indoors Aquaponic Farm:

Wait! Don’t we talk about LED lights here? Don’t we talk about heating the building? That’s what everyone else focuses on. (Just wait, we’ll talk about LED lighting and “heating the building” extensively in our lighting discussion to follow…)

The most important thing to know about indoors growing is that the lights you use ADD so much heat to the building that you’ll need a big A/C unit just to keep the temperature down to a reasonable level! We’ll give you all the numbers and show you why in a subsequent Part of this series.

Unless you’re in Alaska, Northern Canada, or Mongolia, you’ll even need to run that A/C unit in the wintertime! Even in the wintertime, your lights put out so much heat that they’ll heat your grow space up into the ‘80’s and ‘90’s or higher. And if you have to run your A/C during the wintertime to keep an indoors grow cool, imagine how much you’ll have to run it in the summertime!

But perhaps you’ve heard: “flourescent lights are really efficient and hardly give out any heat”. That’s true, compared to standard incandescent lights, which put out 96% of their electrical consumption as waste heat; but that doesn’t mean flourescents don’t give out any.

A “High Output” T5 flourescent light puts out 13% of the incoming electricity as light, and 87% as heat. This is called “waste heat”, because it doesn’t do you any good. It’s literally garbage that you have to get rid of (and at a high cost!) by purchasing and running a big A/C unit. And you need to buy two flourescent lights to put out the same amount of light that a single 13%-efficient LED puts out; this means that the flourescents put out twice as much waste heat as an LED providing the same amount of light.

So, the answer to that problem must be LED lights, right? They’re even more efficient than flourescents, so won’t they solve this problem?

Let’s look at the numbers for LED’s: the best LED lights are 44% efficient, and give out 56% waste heat; but most are down around the 12% efficiency level, and give out 88% waste heat. We’ll come back to these numbers in a bit.

“I already have a warehouse or building with A/C”

Even if you have an existing warehouse or storage building that “already has” A/C, it’s way undersized for handling the additional waste heat that the thousands of watts of light you’ll use will generate. You will need to upgrade it, or add an additional A/C system to handle the additional heat load that the lights impose on it. You may also need to install an additional “electrical service”, for powering both the lights and the air conditioning.

This is a fact. And it’s not an obvious one, unless you’re a mechanical engineer (that’s a term for an air conditioning engineer). So if you have any doubts about this, or are simply hoping your indoor grow will work, consult an engineer. Take them the specifications of the lights you plan to use, how many of them, and how big the space you’re putting them in is. Even if you like to believe in fairies at the bottom of the garden, talking to a mechanical engineer about how much A/C unit you need to buy, and how much electricity will be required to run it, will get you back into reality quickly.

Even knowing this, if you insist on going ahead with your indoors grow, you should consult your electrician and a local mechanical engineer, see if 3-phase service is available at your location, and put in a single 208Y/120V 3-phase service in the size the engineer recommends instead. You’ll be able to run all your single-phase 120 volt AC lighting, aquaponic equipment, and other A/C equipment off this. A 3-phase air conditioning unit will use less electricity, and cost much less to run than single-phase A/C equipment.

There is a bright side! Because you’re not dependent on daytime sunlight for your plants to grow, you can run the lights at night (rather than during the day). This will leverage the nighttime cool and cost you less to run the A/C than running it during the daytime.

Now, isn’t that naturally-lit aquaponic operation in a greenhouse starting to look more attractive?

We are now sending our newsletters in the form of links to these blog articles; they’re on our own website so you can search them easily using the “Find What You’re Looking For” search bar in the left hand column, or the “Categories Of Articles On Our Site” Category pulldown menu!

Learn The Ins and Outs Of Indoors and Vertical Aquaponics! Part 2

For part 1 click this link:

Part 1

Vertical Aquaponics, Part 2:

Over this series, we’re including the information in our “Aquaponics For Millionaires” disclosure package at no charge. We’ve been selling this information package for $1,000 (because to a millionaire, that’s like a cup of coffee is to you, right?).

Let’s Talk Story About Vertical Aquaponics:

“Talking Story” in Hawaii means chatting with family, neighbors, and friends. We’re going to talk story about the high costs for lighting and air conditioning we’ve just found out about, and the relative efficiency and “waste heat” output of the different kinds of lights, so we can be sure you understand the situation.

This is the most important thing to understand about indoors growing: ALL lighting choices for ALL indoors growing technologies have the same drawback: they all put out waste heat that you have to remove with air conditioning.

In other words, you get to pay for your electricity twice: once when you buy it for the lights, and a second time to remove the waste heat the lights dump into your growing space.

(Below) Some not-efficient LED’s that help the indoor aquaponics farm Farmed Here go bankrupt in March of 2017.

As we would say in our local pidgin: “Dis lighting ting is a real bummah, brah!”. If you don’t pay attention and understand the lighting issues and trade-offs, your indoor grow can get so economically out of hand it can go bankrupt in a short time.

LED LIGHT COMPARISON:

Let’s look at an example: Let’s compare a “top-end” 44% efficient 100-watt LED to an “average” inexpensive 100-watt LED that is 15% efficient. The top-end LED puts out 44 watts of light and 56 watts of waste heat.

Even though the average LED also uses 100 watts of power, it only puts out 15 watts of light, so you need three of them to put out the same amount of light as the 44% efficient, top-end LED puts out.

In other words, you have to buy three of the “inexpensive” lights to equal one of the “top-end” LED’s.

PAR LIGHT:

In addition, these inexpensive lights do not put out as much PAR light as the top-end LED’s do. What’s PAR light? PAR stands for Photosynthetically Active Light; that’s light that the plants actually use.

In addition to putting out less light, the inexpensive LED’s also put out less PAR light, so you really need four of them to equal the amount of usable light that one 44% efficient LED puts out. They don’t look so inexpensive now, do they, if you have to buy four times as many!

WASTE HEAT:

That’s not the end of the story: an LED that’s only 15% efficient puts out 85% waste heat. That’s 85 watts of waste heat from a 100-watt light. Since you have four of these lights, you are putting out 340 watts of waste heat (4 X 85 watts = 340w).

GETTING RID OF THAT WASTE HEAT:

At 340 watts of waste heat, the 4 “inexpensive” LED’s put out SIX TIMES AS MUCH WASTE HEAT AS THE “TOP-END” LED, which only puts out 56 watts of waste heat!

I hate shouting with all-caps, but this is REALLY important: can you see it yet? If you choose your lights based on price rather than efficiency, you have to buy four times as many inexpensive, inefficient lights; and that’s expensive!

Because those inefficient lights put out 6 times as much waste heat, you’ll also have to buy an A/C unit 6 times bigger, and spend 6 times as much paying for electricity to run it, FOREVER!

Does that mean that if I buy 44% efficient LED’s, my indoors aquaponic farm will be sure to make money?

It’s too early to tell; because we’ve just scratched the surface of the issues you’ll have to deal with.

More in Part 3 of this series!

Now, isn’t that naturally-lit aquaponic operation in a greenhouse starting to look more attractive?

We are now sending our newsletters in the form of links to these blog articles; they’re on our own website so you can search them easily using the “Find What You’re Looking For” search bar in the left hand column, or the “Categories Of Articles On Our Site” Category pulldown menu!

Learn The Ins and Outs Of Indoors and Vertical Aquaponics! Part 3

For parts 1 and 2 click these links:

Part 1

Part 2

Vertical Aquaponics, Part 3:

(Below) Some not-efficient LED’s that help the Chicago indoor aquaponics farm Farmed Here go bankrupt in March 2017.

The Relative Efficiency of Different Types Of Lights:

I realized in Part 2 I didn’t explain “Waste Heat” very well, so here goes: even though LED’s don’t put out much heat, they do put out heat; even the 44% efficient ones. In an enclosed space, such as an indoors aquaponics farm, that heat will build up until it’s 100 degrees, 105 degrees, then 110 and 120, and so on. It will probably stop around 130 degrees F. But that’s way too hot for for people, and will fry all your vegetables!

To get a sense of this, imagine a house that has broken air conditioning in Phoenix, Arizona, in the middle of a 110-degree July day. That house will get up into the 130-140 degree range within a few hours. So will your indoors farm, until you do something about it. And the best thing to do is to get the most efficient LED’s on the market, then put in the right size air conditioning unit to handle the waste heat from those lights.

1. THE BEST CHOICE: the high-efficiency, high-output LED’S flourescent lights that are made by Nick Brumm, the owner of Nextlight Systems. Nick’s lights use Cree LED’s (they’re the best), are 44% efficient, and only generate 56% waste heat. They also mimic the “spectrum” of natural sunlight almost perfectly, so they are 50% to 100% more efficient at delivering PAR light that the plants can actually use. What’s PAR?

PAR stands for Photosynthetically Active Radiation, and is the only accurate way to compare two or more lights to each other. Lumens, the measure most lighting manufacturers use to rate their lights, are meaningless unless combined with a PAR light rating; the amount of lumens a light puts out doesn’t tell you anything about how much usable light the plant is getting.

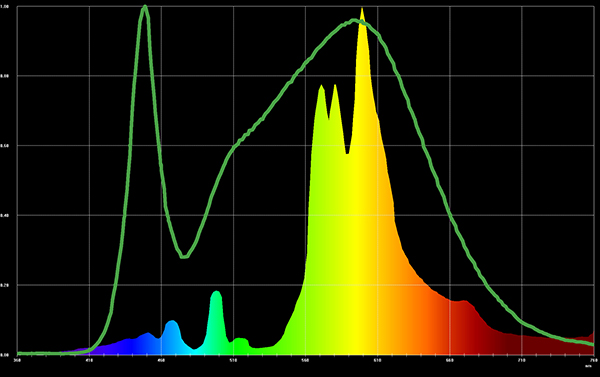

(Below) The light spectrum of one of Nick’s Mega LED Grow Lights, that uses 525 watts, is the green line; the colored rainbow is the spectrum of an HPS 1000 grow light; a standard for the last 30 years, but one which uses 1,100 watts, and puts out four times as much waste heat as Nick’s light does.

Nick’s lights use a high-quality LED chip manufactured with the best dye on the market, so they emit very small amounts of waste heat; as a result, they DON’T need to be water-cooled like some other “vertical farming LED’s” do!

(Below) One of Nick’s Mega LED Grow Lights that will cover a 7-foot by 7-foot area of indoor aquaponic plants! Expensive, but they are really CHEAP because they require so little electricity for both lighting and air conditioning to get rid of waste heat.

Although the people who sell those water-cooled lights will try to tell you that the water-cooling is a “feature” and a benefit, water cooling an inefficient LED uses just as much electricity as an air conditioner would to cool the air, if the same lights had no water cooling. The whole “water-cooled” thing is just a head fake to keep you from seeing the real problem: these LED’s are inefficient, and you’re going to have to spend a ton of money getting rid of the waste heat from them

You can email Nick at nick@nextlightsystems.com, and help convince him you are an emerging market for his products. Just say: “We’re building an indoors farm, and we’d like you to price some efficient lights for us”. These are the perfect lights for an indoors farm, and will save you tens to hundreds of thousands of dollars on electrical costs for lighting your farm and for air conditioning to get rid of the waste heat.

The more lights he sells, the more the price for those lights is going to come down. They also offer a “lease to own” program, so you don’t have to purchase the lights outright, with a big u1pfront cost. You can see their current product line at Nextlight.com

2. AN EXPENSIVE AND INEFFICIENT ALTERNATIVE: The “other” LED’s on the market are less efficient than this; they only convert 9-20% of the electricity into light, and convert 80-91% into heat. You need two to five times as many lights, which means you will be using two to five times as much electricity for the lights. And, as we’ve learned in this series, you will ALSO have to install an air conditioning unit TWO TO FIVE TIMES AS BIG as the one requires by the lights described in #1 above.

3. An even more expensive and inefficient alternative: Flourescents: Flourescents are not much good. Even high-efficiency, high-output flourescent lights like the T5HO’s are only about 13% efficient in converting electrical energy into light to your plants. The other 87% of the electricity is emitted by the lights and their “ballasts” as waste heat into your growing area.

That doesn’t sound too bad until you understand that a flourescent uses approximately twice as much electricity as even a 13% efficient LED, so it puts out twice as much waste heat for the same amount of light. If you go back to #2, and do some simple math, you’ll realize that flourescents will use four to ten times as much electricity for both lighting and getting rid of the waste heat, as do 44% efficient LED’s.

4. Other types of lights: sodium vapor, halogen, mercury vapor, all use a LOT of electricity for the amount of light they put out, and put out an incredible amount of heat compared to even flourescents. They are what you’d use if you owned the electric company and the company that makes them.

We’ll talk about other factors influencing success or failure in indoors growing in Part 4 of this series!

Learn The Ins and Outs Of Indoors and Vertical Aquaponics! Part 4

For parts 1 through 3 click these links:

Part 1

Part 2

Part 3

Vertical Aquaponics, Part 4:

First, some additional reading to round out your knowledge of the issues involved in vertical and indoors farming: here’s a link to download a scholarly critique by Stan Cox and David Van Tassel, plant breeding researchers at The Land Institute in Salina, Kansas (www.landinstitute.org), of Dickson Despommier’s claims that vertical farming is the answer to our current struggle to produce enough food with conventional farming.

How Many Plants Do You Need To Be Profitable?

In our last Part, we talked about the relative efficiency of the different kinds of lights available, and how inefficient lights result in a huge electric bill AND a huge air conditioning unit and bill.

We concluded that 40%-+ efficient LED’s were pretty much the only ones you can afford, because they’re the only ones that result in the absolute minimum of air conditioning required (if that sounds confusing, just re-read Part 3, above). It turns out that buying air conditioning and electricity to make up for using inefficient LED lights can really break your bank and bankrupt your farm!

In this Part, we’ll discuss how many plants you need to have in your space for it to be profitable. The most comprehensive way to show that information is a spreadsheet of an indoors aquaponics operation in a building of about 10,000 square feet, which you can download using the link below:

Click on this link to download the data in spreadsheet form.

For those of you who don’t “do” spreadsheets, we offer an example of how this works:

First, your farm has fixed costs for the building (either rent or mortgage), things like insurance, property tax, signage, advertising and marketing, accounting and legal expenses, and depreciation. Together they are referred to as fixed costs or “overhead”: that is, you have these expenses even if you don’t produce a single head of lettuce! They are expenses that don’t directly contribute to the production of a profit.

Your farm has other expenses too: these are usually called “operating expenses”, and are things directly connected to, and in proportion with, what is being produced. These are expenses such as seeds, potting mix, fish fingerlings, fish food, labor and management wages and benefits, electricity, water and natural gas, packaging, shipping your products to the buyer, and so on.

It’s obvious that if you add all your overhead costs and all your operating costs for a year, then divide by the dollar value of the plants you sold in a year (not produced, not the same thing at all!), then you’ll have an accurate picture of what it cost to produce each plant you sold. If you sold the plants for more than the total of your operating and overhead expenses, then you made a profit.

What’s not quite so obvious is that the more plants you have in your growing space, the less each plant costs you to grow. This is because your overhead costs you less per plant. If you have 100 plants and a yearly overhead of $10,000, then each plant costs you $100 worth of overhead to grow; obviously not a profitable business!

If you’ve got 40,000 plants with the same overhead, then your overhead per plant is 25 cents. Now it’s much more likely you can make a profit. You still need to add in the operating expense to get an accurate picture of your cost per plant. But operating expenses work in a similar fashion to overhead: the more plants you grow on a certain amount of operating expense, the less each plants costs, and the more likely you are to make a profit.

Where are we going with this? Just trying to show you how important it is that your proposed vertical or indoors growing technology have a minimum plant density per square foot of building area, or there’s no chance of it ever being profitable.

In our spreadsheet example, our growing technology holds 17.67 plants per square foot of building floor space, or a total of 176,700 plants in 10,000 square feet. This includes all plants at all stages of growth: those in the rafts as well as those in the sprouting tables. Check this number against the number of plants your proposed growing technology holds per square foot.

If yours is less, I’d be concerned. If it’s half or less, then feel free to give us a call. But we’ll show you exactly how we get that many plants in this small an area (using our CAD drawings of this facility) in one of our next Parts of this series.

(Below) Some not-efficient LED’s that help the Chicago indoor aquaponics farm Farmed Here go bankrupt in March 2017.

We’ll show you how to design a profitable indoors growing facility, and how you get that many plants in an indoors grow in Part 5 of this series!

Learn The Ins and Outs Of Indoors and Vertical Aquaponics! Part 5

For parts 1 through 4 click these links:

Part 1

Part 2

Part 3

Part 4

Vertical Aquaponics, Part 5:

High-Density Planting Strategies And Specialized Techniques For All “Greens” Crops

This is the million-dollar secret high-density planting strategy Susanne developed in 2010; although this is covered in much greater detail in our manuals and our live courses (17 pages in the manual, with lots of photos; and a 1-1/2 hour presentation in the live course), we have NEVER presented this information publicly except at our live courses. We use this in our proprietary vertical aquaponics systems, which you’ll see a little later in this series of articles.

We’ve put a simplified version into this article. All the information is here for you. If you’re smart; you can figure out our planting system. Susanne figured this out on NO information; she just invented it. She’s really smart. Want the complete version with lifetime free technical support? Purchase the Commercial Aquaponic DIY Package, or come to one of our 5-day live courses.

1. Soak your coconut coir in aquaponics water overnight, then it breaks up easily; mix with 40% vermiculite by eye to make potting mix; be sure to wear a cartridge respirator until the vermiculite is damp and no longer a breathing risk.

2. Fill 98-cell nursery trays by putting a number of trays on a work table and dumping the mix on top of them, then “sweeping it” from tray to tray until it fills them all; pick up each tray by the ends and bump it down onto the table 2 or 3 times to “settle” the mix in the cells.

3. Plant by hand by putting seeds directly on top of the potting mix in the trays, using pelleted seed whenever possible. There is no need to “dimple” the potting mix first; simply put the seed on top.

4. Sprinkle a light covering of plain vermiculite on top of each tray, wearing a cartridge respirator if using dry vermiculite. Top-water the trays with a watering can using aquaponic water, then place into the sprouting tables.

5. Keep sprouting tables and sprout trays at least 70 degrees F until the roots have just barely come out of the holes in the bottom of the nursery trays, then transfer into 2-inch slit pots and into your 55-hole 2-foot by 2-foot rafts in the aquaponics system. We use little 3-prong dessert forks for this; we tried everything and found they were perfect! When you do this transfer, CULL OUT all stunted and unhealthy plants and put them in the compost! (how can you do that to the poor little baby plants?) They never do catch up, and if you transfer them to the rafts, you’ll have wasted your labor and money on a substandard produce item you won’t be able to sell. We typically cull 15% here WHEN EVERYTHING IS PERFECT!

6. When the plants have grown around 4-5 inches high, transfer them from the 55-hole rafts to the 34-hole rafts for final grow-out and harvesting. Once again, CULL OUT all stunted and unhealthy plants during this transfer also! We typically cull 15% here WHEN EVERYTHING IS PERFECT! As a result of these two culling steps, each raft of greens we harvest out of the system is nearly perfect!

Because of the higher density of the plants in “the 55’s” (13-1/2 plants per square foot), you end up with an average of 6.45 plants per square foot of system area when combined with the 4 plants per square foot in the 34-hole 2-fot by 4-foot grow-out rafts.

7. Another way to use the 55’s is to plant green onion, chive, radish, or leek seeds directly into the 2-inch slit pots, and bypass the sprouting table completely, putting the pots directly into the aquaponics system for these plants to grow all the way to maturity. This puts an incredibly high density of these plants into each square foot of the system.

Eradicate Mosquitoes With Aquaponics!

Possibly the most important HEALTH benefit of farming aquaponically (that we noticed after our first system was operational for six months) was that the mosquitoes on our seven-acre farm had COMPLETELY disappeared! We live in Hawaii, [Read more…]

USDA Organic Certification For Your Aquaponic Farm:

We often hear: why bother? Doesn’t it cost money? Here’s some REALLY good reasons to do it:

Consumers are willing to pay 50-90% more for organically certified produce than conventionally grown produce; this means [Read more…]

Low Density Systems

“Low Density” refers to the relatively low density of fish required for excellent vegetable growth. Our Low Density (or LD) systems only require four major components: a fish tank, vegetable troughs, a water pump, and an air pump [Read more…]

Aeration, Air Pumps, Blowers, And Airstones

Aeration can be done in all kinds of ways using all kinds of equipment and methods: airlift pumps, water sprays, paddlewheels, rotors, blowers, compressors, etc. They all use MORE [Read more…]

Raft Discussion

WARNING! There has been discussion among attendees of our courses about alternatives to the Styrofoam rafts we use (which were approved for organic certification by Oregon Tilth), [Read more…]

- 1

- 2

- 3

- …

- 5

- Next Page »