How Greenhouses Work, Part 1

This is the first part of what’s probably going to be an 8 or 10-part series by the time we’re done. That’s because there’s a LOT of ground to cover to explain, in a simple, easily understandable way, how greenhouses work, how much greenhouse you need in your location, and how to get the best greenhouse for the least amount of money. As part of this series, we’ll show you how to get FREE greenhouses; one of our students got a $1.4 million greenhouse just for taking it down and hauling it away.

We’re lucky we live in Hawaii, but not everyone has the same near-perfect outdoors growing season we enjoy. Climate limits you to growing outdoors with aquaponics only during the spring and summer in temperate climates, and to year-round growing in tropical climates.

Because of this, and the fact that people like to eat fresh food all year-round (not just during the normal growing season) we spent a year in 2012 increasing our understanding of greenhouse technology. Our goal was to incorporate an energy-efficient greenhouse technology with our aquaponics technology to create complete systems that will grow year-round ANYWHERE economically without too much concern for the weather.

We were initially discouraged by conventional petrochemical-driven greenhouse technology, which uses fossil fuels for heating in the winter and cooling in the summer. It was common to see thousand-gallon propane tanks sitting outside a greenhouse to provide winter heat, and a huge three-phase electrical service leading into the building, hooked up to several huge air conditioners for summertime cooling.

While these methods do work, and were profitable in 1970 when oil was cheap, today these methods are so costly in terms of oil AND dollars that they will put your commercial aquaponic farm out of business.

We were shocked by how little information was available on the subject of affordable, energy-efficient greenhouses. We realized this was because the “greenhouse establishment” can’t make money selling them. They make money from selling greenhouses with electrically-powered fans, air conditioners, thermostatic controllers, electrically-operated vents, propane heaters and ducting, because they sell that stuff also. Then, making a profit becomes your problem after you pay for the energy to run everything. That’s why there are so many used greenhouses for sale now.

We knew an appropriate technology MUST exist, but it wasn’t easy to find in 2012. We thought we would have to develop it ourselves out of thin air. Although we were game for the task, it was daunting to consider, even though we know a lot about construction, refrigeration, cooling, heating, and alternate energy technologies.

At first, what we found had little to no information on “energy-light” methods of modifying the environment inside the greenhouse, such as passive solar heating and geothermal cooling. There was no inclusion of PV panels or other sustainable alternate energy sources in the energy schemes used to power these greenhouses.

When we did find our energy-efficient greenhouse model, we were shocked: it wasn’t high-tech aluminum and glass; in fact, it wasn’t very high-tech at all. The first ones were built around 1200 AD, and the design hasn’t changed much since then: it’s the Chinese-style greenhouse.

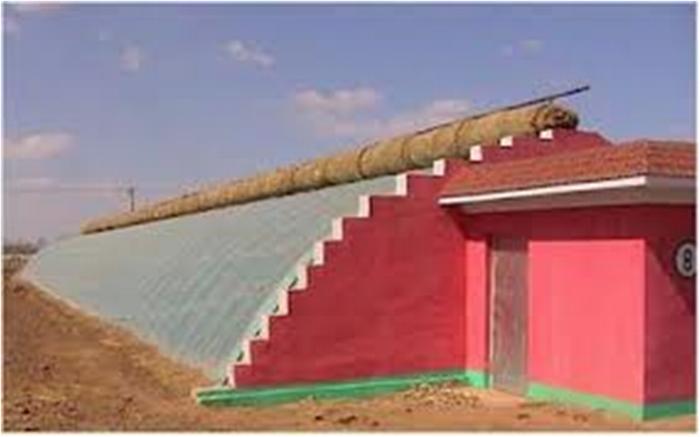

(Below) A VERY modern Chinese-style greenhouse; we’ll talk a LOT more about this type of greenhouse during this series of articles.

The Chinese have had to do a lot with few resources for centuries. As a result, they are very creative and productive when it comes to designing appropriate technology. Here’s what they did to make their greenhouses the best in the world, for the least cost:

The Chinese-style greenhouse is oriented long ways North to South, and has one long clear side facing South to let sunlight in for winter warmth. The other long side is on the North, and because no sunlight ever comes from the North, and that wall doesn’t bring any light in to the plants (if you’re in the Northern hemisphere), they made it a double wall of brick and insulated it with hay bales to keep warmth in. The North wall also helps to keep the greenhouse cool during the summertime.

(Below) A big, PINK Chinese greenhouse showing the dirt over the plastic film skirt, the thermal blanket in the daytime rolled-up position, and the “airlock” for the workers so they don’t open the greenhouse door directly to the cold winter air. The airlock also serves as a place to hang up heavy winter coats and exchange rubber boots for the slippers the workers wear inside an 80-degree F greenhouse.

They also made the shorter East and West end walls solid and insulated them, because they found that the plants grew just as well if these walls were solid; the plants apparently got plenty of light. We verified this with our first Chinese-style greenhouse.

They gave their greenhouse a curved roof that slopes down to the very low South wall, a wall that is so short that just barely provides enough headroom for the workers inside. But by doing this, they got rid of a lot of roof area and wall area, compared to the Western-style greenhouse designs with full-height walls on all four sides, and peaked or pointed roofs. This was good, because they not only had to build less roof and walls, but also had less roof and wall area to leak heat out into the environment in the winter.

(Below) Almost night-time; 78 degrees F inside, -12 outside. Plants are getting a little supplemental light in the relatively sunless Wisconsin winter.

Then they really iced the cake; they put a blanket over the greenhouse at night to keep the daytime warmth in. This isn’t a blanket like on your bed; Chinese greenhouse themal blankets are made of straw, and are about six inches thick, woven out of waste farm materials and natural fiber. And boy do these straw blankets ever insulate!

When the workers leave the greenhouse in the early evening, they roll the straw thermal blanket down over the plastic greenhouse covering and secure it against the wind. The first workers to arrive in the morning roll the thermal blanket up and secure it in the up position, just in time for the greenhouse to begin receiving the first warming rays of the day’s sunshine.

The Chinese technology is just about as low-tech as it gets: brick walls, hay bales for insulation, and straw for thermal insulation. The highest-tech materials are steel rebar (used for the curved trusses that hold the plastic covering up), the plastic film itself that they cover the greenhouse with, and some bug screen which is applied to the greenhouse in the summertime to help keep out insect pests.

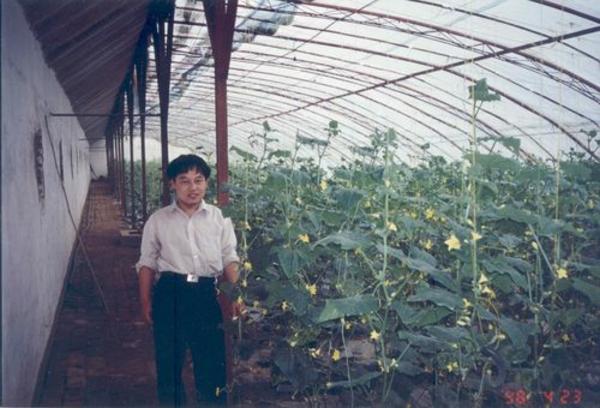

(Below) Chinese greenhouse in operation in the summertime, note bug-screen-covered vents abov the farmer’s head, and simple construction of rebar trusses and thin-wall metal tubing.

To vent the greenhouse in the summertime, they simply rake the dirt off the “skirt” of plastic on the outside of the greenhouse that was holding that edge of the plastic down all winter long, and roll the plastic up about five to seven feet off the ground to create a vent to bring cooler outside air into the greenhouse, which they then cover with the bug screen. They use this same technique to create ridge vents up near the top of the North wall, which help vent excessive heat from the greenhouse.

(Below) Notice the rolled-back plastic at the top middle; this is the “ridge vent”, and the rolled-up plastic at the lower right, covered with bug screen; this is the cool air inlet vent.

Leave a Reply