Learn The Ins and Outs Of Indoors and Vertical Aquaponics! Part 3

For parts 1 and 2 click these links:

Part 1

Part 2

Vertical Aquaponics, Part 3:

(Below) Some not-efficient LED’s that help the Chicago indoor aquaponics farm Farmed Here go bankrupt in March 2017.

The Relative Efficiency of Different Types Of Lights:

I realized in Part 2 I didn’t explain “Waste Heat” very well, so here goes: even though LED’s don’t put out much heat, they do put out heat; even the 44% efficient ones. In an enclosed space, such as an indoors aquaponics farm, that heat will build up until it’s 100 degrees, 105 degrees, then 110 and 120, and so on. It will probably stop around 130 degrees F. But that’s way too hot for for people, and will fry all your vegetables!

To get a sense of this, imagine a house that has broken air conditioning in Phoenix, Arizona, in the middle of a 110-degree July day. That house will get up into the 130-140 degree range within a few hours. So will your indoors farm, until you do something about it. And the best thing to do is to get the most efficient LED’s on the market, then put in the right size air conditioning unit to handle the waste heat from those lights.

1. THE BEST CHOICE: the high-efficiency, high-output LED’S flourescent lights that are made by Nick Brumm, the owner of Nextlight Systems. Nick’s lights use Cree LED’s (they’re the best), are 44% efficient, and only generate 56% waste heat. They also mimic the “spectrum” of natural sunlight almost perfectly, so they are 50% to 100% more efficient at delivering PAR light that the plants can actually use. What’s PAR?

PAR stands for Photosynthetically Active Radiation, and is the only accurate way to compare two or more lights to each other. Lumens, the measure most lighting manufacturers use to rate their lights, are meaningless unless combined with a PAR light rating; the amount of lumens a light puts out doesn’t tell you anything about how much usable light the plant is getting.

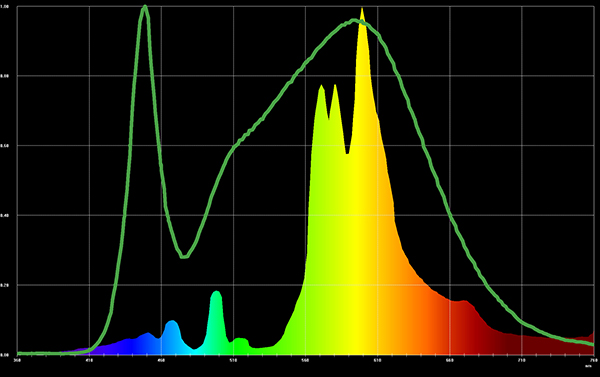

(Below) The light spectrum of one of Nick’s Mega LED Grow Lights, that uses 525 watts, is the green line; the colored rainbow is the spectrum of an HPS 1000 grow light; a standard for the last 30 years, but one which uses 1,100 watts, and puts out four times as much waste heat as Nick’s light does.

Nick’s lights use a high-quality LED chip manufactured with the best dye on the market, so they emit very small amounts of waste heat; as a result, they DON’T need to be water-cooled like some other “vertical farming LED’s” do!

(Below) One of Nick’s Mega LED Grow Lights that will cover a 7-foot by 7-foot area of indoor aquaponic plants! Expensive, but they are really CHEAP because they require so little electricity for both lighting and air conditioning to get rid of waste heat.

Although the people who sell those water-cooled lights will try to tell you that the water-cooling is a “feature” and a benefit, water cooling an inefficient LED uses just as much electricity as an air conditioner would to cool the air, if the same lights had no water cooling. The whole “water-cooled” thing is just a head fake to keep you from seeing the real problem: these LED’s are inefficient, and you’re going to have to spend a ton of money getting rid of the waste heat from them

You can email Nick at nick@nextlightsystems.com, and help convince him you are an emerging market for his products. Just say: “We’re building an indoors farm, and we’d like you to price some efficient lights for us”. These are the perfect lights for an indoors farm, and will save you tens to hundreds of thousands of dollars on electrical costs for lighting your farm and for air conditioning to get rid of the waste heat.

The more lights he sells, the more the price for those lights is going to come down. They also offer a “lease to own” program, so you don’t have to purchase the lights outright, with a big u1pfront cost. You can see their current product line at Nextlight.com

2. AN EXPENSIVE AND INEFFICIENT ALTERNATIVE: The “other” LED’s on the market are less efficient than this; they only convert 9-20% of the electricity into light, and convert 80-91% into heat. You need two to five times as many lights, which means you will be using two to five times as much electricity for the lights. And, as we’ve learned in this series, you will ALSO have to install an air conditioning unit TWO TO FIVE TIMES AS BIG as the one requires by the lights described in #1 above.

3. An even more expensive and inefficient alternative: Flourescents: Flourescents are not much good. Even high-efficiency, high-output flourescent lights like the T5HO’s are only about 13% efficient in converting electrical energy into light to your plants. The other 87% of the electricity is emitted by the lights and their “ballasts” as waste heat into your growing area.

That doesn’t sound too bad until you understand that a flourescent uses approximately twice as much electricity as even a 13% efficient LED, so it puts out twice as much waste heat for the same amount of light. If you go back to #2, and do some simple math, you’ll realize that flourescents will use four to ten times as much electricity for both lighting and getting rid of the waste heat, as do 44% efficient LED’s.

4. Other types of lights: sodium vapor, halogen, mercury vapor, all use a LOT of electricity for the amount of light they put out, and put out an incredible amount of heat compared to even flourescents. They are what you’d use if you owned the electric company and the company that makes them.

We’ll talk about other factors influencing success or failure in indoors growing in Part 4 of this series!

Are there more information regarding about this topic for us to research for? Thank you, Regard Telkom University

Can you highlight any innovative or groundbreaking concepts introduced in Part 3 regarding indoor and vertical aquaponics?